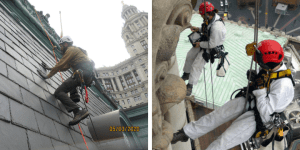

There’s a subset of LinkedIn posts that emphasizes the daredevil side of facade inspections with dizzying pics of rope access team members hanging high above the city. We understand that rope access has its thrilling side, but should it be the go-to method for facade inspection?

Sometimes, it’s the best (or only) way to access certain areas like mansard roofs or hard-to-reach corners. But it should be employed strategically, in combination with other means of facade access like platform lifts (which can reach 300 feet), swing staging, and pipe scaffolding.

Rope access comes with limitations: reduced mobility during inspection; the narrow width of the inspected region, especially near the top of the drop; limited ability to remove unsafe or precarious conditions; and the difficulty of performing probes, hampering investigation of how facade components are put together.

Then there’s the issue of rope access technicians’ professional development. In order to be safe, you’ve got to be out there consistently to keep current. But while you’re hanging from a rope, you’re not developing other skills.

After inspection information is gathered through rope access, how are facade defects remedied and how are the solutions expressed in clear drawings and specifications? Time on a rope is time not spent drawing, writing, or consulting with colleagues.

And how are solutions implemented by the contractor? The crucial construction administration task of inspecting actual repairs as they occur is done from swing staging, not on ropes.

What about client contact? It’s tricky—if not impossible—to Zoom while on a rope.

Indiana Jones may have been a great archaeologist and professor, but there are few scenes of him in a classroom. That’s because research and preparation don’t make for the most sensational content. But they are essential to devising a building envelope access plan that’s logical, safe, and cost-effective. Sometimes, the real heroes are behind the scenes, not dangling from facades.

14 Wall Street, 25th Floor, New York, NY 10005

(212) 505 1133

info@superstructures.com

Subscribe to SuperScript, our email newsletter.