From the Owner (and/or Property Manager’s) Point of View

Your building envelope has a problem: water intrusion, cracks at the corners of the facade, a century-old coating of grime.

A restoration engineer or architect (E/A) will start by investigating and verifying the nature of your building’s issues (e.g. determining the source of water infiltration causing your leak).

Eventually, the E/A will guide the process from identification of the problem through construction documents, contractor selection, execution of the remedial measures, and compliance with the Department of Buildings (DOB) regulations.

From the E/A Point of View

Exterior restoration is both art and science.

The science of exterior restoration entails an understanding of the factors that can compromise the building envelope, coupled with a thorough knowledge of remedial measures—their design, cost, and implementation.

The art of exterior restoration entails the design of solutions that are either virtually invisible or enhance the building’s appearance once implemented.

How does a project proceed?

Success of a restoration project is determined by collaboration between the owner, the E/A firm, and eventually, the contractor.

The project begins with an understanding of the owner’s expectations, priorities, budget, and schedule. Generally, the project proceeds in four basic chronological phases:

SUPERSTRUCTURES has developed a proprietary methodology—unique in the profession—that shapes the entire life cycle of the project through each of these phases. This offers unprecedented control over each project phase—a feature that’s unfortunately best appreciated in its absence.

One of our main mantras is borrowed from the Hippocratic Oath: “first, do no harm.”

Some E/As have been involved in thousands of projects. However, each building and owner is unique, and the E/A should approach each assignment not with a cookie cutter, but with an open mind.

Investigation, Analysis, and Reporting

Information is the E/A’s currency. The E/A collects it thoroughly yet economically, analyzes it expertly, and communicates findings clearly to the owner and to the contractors who execute the remedial work.

The investigation phase follows the classic scientific method: gathering available data, including existing reports, drawings, and research on similar buildings and construction types from past projects, analyzing it objectively, and reaching logical, consistent conclusions.

When E/As look at the exterior of a building, we see "symptoms" of distress. In specifying remedial work, it is important to understand the root cause; otherwise, the repair treats only the symptoms.

The first step is to obtain and assimilate as much information as practical about the subject building’s condition—its history, underlying construction, and symptoms of distress.

Review of Information

The E/A reviews available, relevant documentation, including prior engineering reports, repair history, original building blueprints and specifications, and DOB records.

Visual Condition Survey

Eyes are invaluable tools for visual condition surveys of a building—either in person or off-site review of photographs. Visual surveys can be conducted from vantage points on the ground, via scaffolding or platform lifts, and documented using high-magnification digital cameras.

UAS (Drone) Digital Imaging

In our experience, UAS (Unmanned Aerial Systems, aka “drones”) can provide the E/A with an array of high-definition, inspectable images of the building facade. In some cases, drone imagery can eliminate the necessity for erecting expensive scaffolding to inspect hard-to-access locations (e.g., towers and turrets).

Advanced Digital Imaging and Reality Capture

SUPERSTRUCTURES has developed proprietary inspection technologies called SurfaceCaptureSM and ConditionCaptureSM, in which thousands of high-resolution digital images are combined to create a composite, two-dimensional digital image or three-dimensional model of the subject structure.

SurfaceCaptureSM and ConditionCaptureSM provide a comprehensive record of the condition of the subject structure and allow our experts to “zoom in” to view a level of detail measured in fractions of an inch.

Physical Condition Survey

Visual surveys are typically supplemented by close-up, physical examinations of representative portions of the building that are used to “calibrate” the visual examination. Methods of access include pipe scaffolding, suspended scaffolding, or truck-mounted boom lifts (some of which can reach heights of 250 feet). Industrial rope access can be used in isolated locations where neither of the two preferred methods are feasible.

Periodic critical examinations mandated by New York City’s Facade Inspection & Safety Program (FISP, or Local Law 11) must include close-up examination, parapet to grade, at 60-foot intervals.

Non-Destructive Testing and Evaluation (NDTE)

NDTE techniques support the investigation phase by allowing the E/A to “see” below the surface of the building envelope.

Using tools and technology such as infrared (IR) cameras, electrical impedance (EI) meters and scanners, ground penetrating radar (GPR) antennas, covermeters, and pachometers, the E/A can gain critical advance intelligence about a building’s underlying construction and condition, with minimal disturbance to its fabric.

Exploratory Probes

When warranted, the E/A specifies and monitors exploratory probes of concealed conditions to determine the configuration of original construction and the extent of deterioration.

Not all buildings are alike. For many older structures, the original construction documents were lost long ago. Limited probes provide an understanding of the unique way (or variation of the standard way) in which the building components were assembled—information essential to restoring them.

Probes are typically performed via the same means of access as physical inspections, reinforcing the advantages of pipe scaffolding, suspended scaffolding, or boom lifts that provide a more robust work platform than rope access.

Th E/A strives to balance the value of the information yielded by the exploratory probes against the attendant expense.

Reporting

The information gathered through review of existing documents, visual surveys, physical examinations, non-destructive testing, and probes is analyzed and organized in a report issued to the owner.

Through careful analysis, the E/A determines the causes of observed deficiencies and, based upon their judgment and experience, recommends appropriate remedial procedures.

Typically, each type of deterioration entails a discussion of observations, analyses, recommendations, and estimated costs. The report includes digital photos, drawings, and diagrams that clarify the narrative.

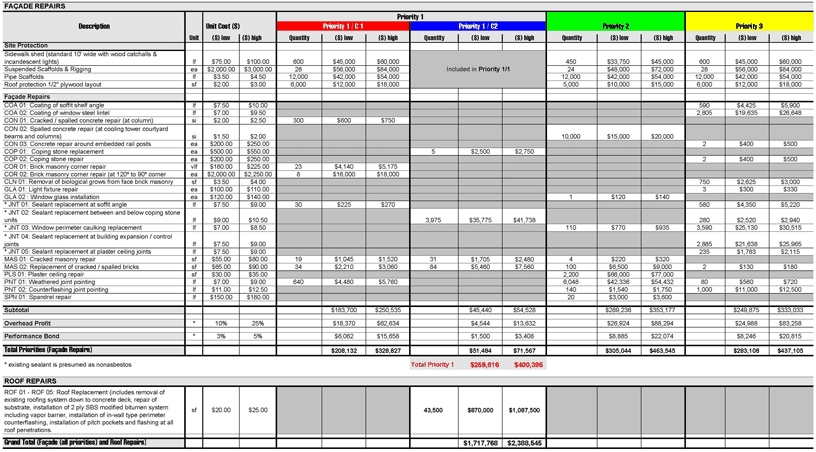

Reports generally include detailed spreadsheets listing recommended remedial action, categorized by priority. Each recommendation is accompanied by an estimate of the associated cost.

Reports (particularly the spreadsheets) are a valuable planning tool that informs the owner’s decision-making process. It enables owners to prioritize and finalize the scope of work to be undertaken, and to quantify and allocate the required resources.

Construction Documents

A successful project involves quality workmanship, completed on time and within budget.

A well-crafted set of Construction Documents (CDs) is key to achieving that outcome.

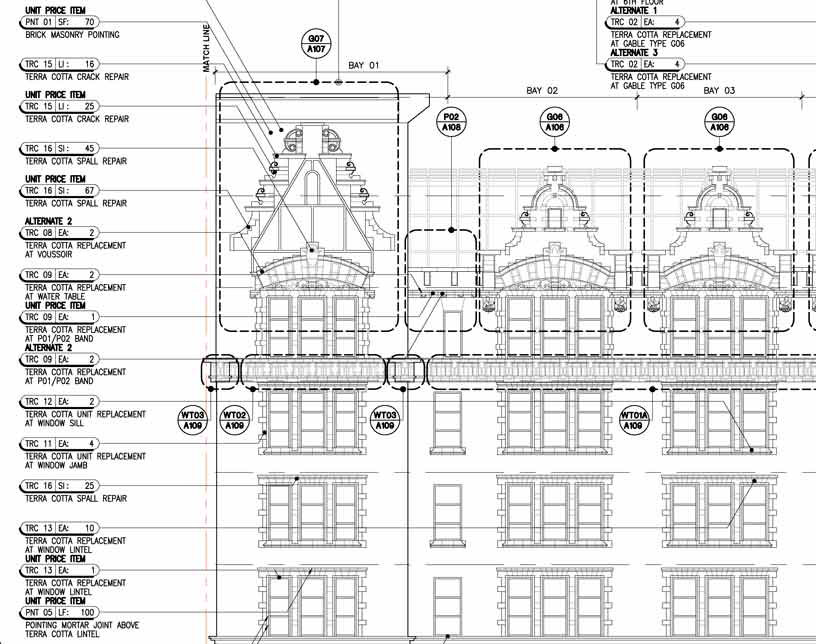

CDs should clearly indicate the type, quantity, and location of the restoration work that needs to be performed to the contractors bidding—and ultimately executing—the work. Each piece of information required by the contractor should be provided in a consistent location and format.

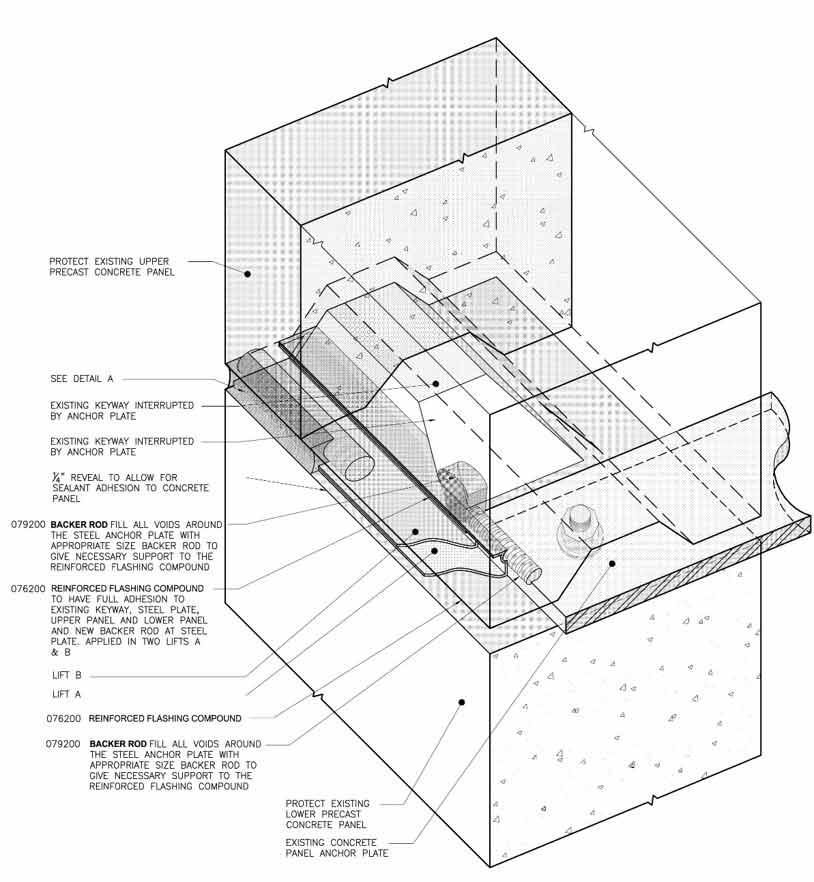

The best way to save both time and money is to develop all the construction details (how specified materials fit together) on paper before contractors go anywhere near the building. Ambiguous language like “replace flashing as required” on a set of drawings leaves many significant issues unresolved. The best practice is to draw every detail rather than relying on verbiage that’s subject to misinterpretation.

The Construction Specifications Institute enumerates the four Cs that CDs should aim for: Clear, Correct, Complete, and Concise.

Typically, CDs include construction drawings (“blueprints”), technical specifications (usually in 8.5 x 11 format), and the project manual, which contains directions for bidders, proposed owner-contractor agreement, insurance requirements, etc.

Bidding/Negotiation

In the Bid phase of the project, the owner ultimately selects a contractor best qualified to implement the work defined by the CDs. But the E/A firm has a role to play here as well.

The E/A can assist in assembling the list of contractors invited to bid on the project. Some contractors are better suited to certain types of projects—e.g. roofing vs. facade, curtain wall vs. terra cotta.

Contractor selection should be based on contractor reputation and demonstrated understanding of / suitability for the project.

A virtually “airtight” set of CDs is critical at this stage, as they open competition to a wider field of bidders, not only those that are known to the E/A.

Owners want a project that’s completed on time and, here again, solid CDs are critical. A construction schedule (and bid) will be reliable only if the scope of work is defined as thoroughly as possible in advance.

Quantity Summary

When CDs are complete, the E/A generates a summary spreadsheet itemizing the quantity of each of the restoration assemblies (details) required for the job. This summary is a more refined version of the spreadsheet generated at the conclusion of the investigation phase.

The summary may be generated for the project as a whole, segregated by phase or facade, or “sliced and diced” in any manner meaningful to the owner.

The CDs distributed to bidders include a version of this summary spreadsheet. Because contractors’ estimators can concentrate on job logistics and implementation strategies rather than rote quantity surveying, they can bid projects more quickly and accurately.

The E/A conducts on-site walk-throughs with bidders to be sure each understands project requirements, as well as special conditions that might impact their bids.

Bid Analysis and Contractor Selection

The E/A assists during contractor selection and negotiations to secure the optimum value for the owner—the best price from the most suitable contractor.

Each bidding contractor is required to submit a lump-sum fee for the entire project as defined in the CDs, as well as a separate line-item price for each restoration assembly.

When retained to do so, the E/A prepares a detailed analysis of bid submissions, comparing competing bids with each other and with historical cost data, item by item.

Often, the E/A attends interviews that include the owner and representatives of bidders under consideration.

Construction Administration

The A/E firm can give owners additional control during the construction phase of the project by conducting professional Construction Administration (CA)—tracking the progress of every item of work performed by the contractor to ensure they’re faithful to the CD’s and on track.

Field observation reports are organized around the labeling system established in the CD’s and each label on the construction drawings represents a unique type of work. In addition, each label is assigned a unique identification “tag” to distinguish it from other restoration labels indicating the same type of work. By referring to its unique tag, every restoration item on the project may be unambiguously identified and tracked.

A spreadsheet is prepared by digitally extracting the labeled and tagged information from the AutoCAD drawings. The spreadsheet lists each labeled item of work, together with its tag, and becomes the basis for construction administration of the project.

As construction progresses, a field team notes the completion percentage of each item of work, together with relevant comments and photographic documentation. The spreadsheet is updated after each site visit, providing an illustrated, up-to-the-day record of the job’s progress that can be emailed to both owner and contractor.

This system assures that the contractor’s applications for payments are consistent with the work actually performed and enables the A/E professional to track the progress of the job in terms of both time and cost.

14 Wall Street, 25th Floor, New York, NY 10005

(212) 505 1133

info@superstructures.com

Subscribe to SuperScript, our email newsletter.